Tempered Hardwood Sheets

Also the smooth surface makes finishing the hardboard.

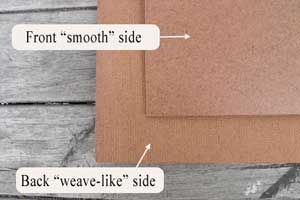

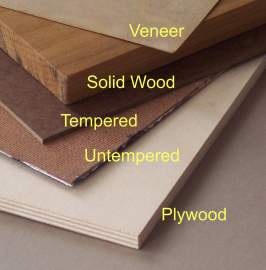

Tempered hardwood sheets. Tempered hardboard or high density fiberboard is an engineered wood board that unlike particleboard is made with ground up wood fibers rather than wood chips and held together with resins. It will stand up to abuse that other woods cannot handle and is perfect for interior and exterior projects when properly finished. Mason and originally manufactured by the masonite corporation. This can be perfect for any type of diy project.

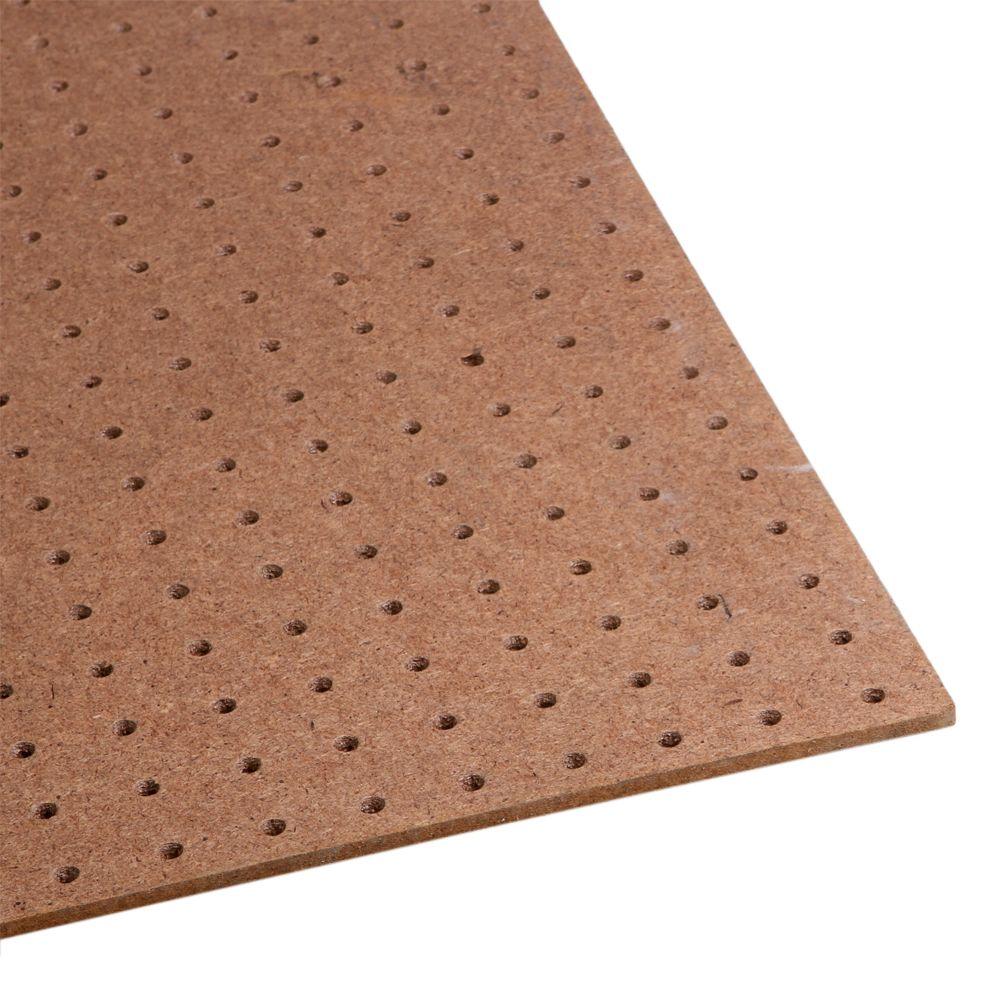

Visit the home depot to buy 1 8 in. Hardboard tempered panel is very cost effective and extremely strong. X 8 ft. The hardboard is rated kdht for moisture content.

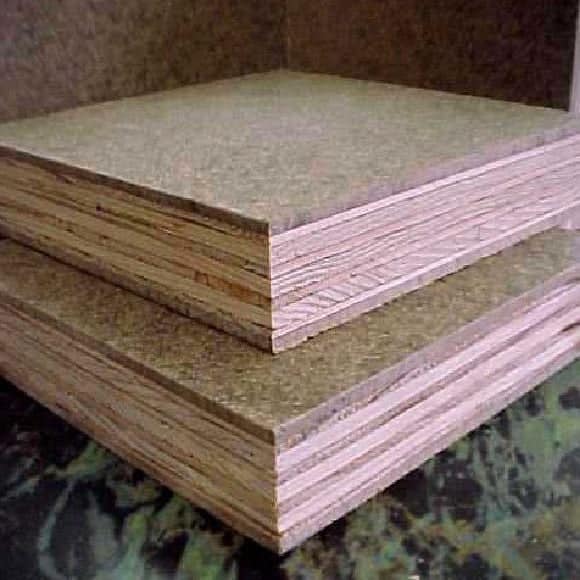

Tempered hardboard is dark brown in color and smooth both sides. Each 7 ply sheet features decorative poplar veneers on the face and back which exhibit the warmth and beauty of natural hardwood to supply your carpentry creations with visual allure. Hardboard tempered panel common. X 96 in model 832780.

Purebond birch plywood fsc certified price. Tempered hardboard an engineered wood product is made from wood fibers that have been tightly compressed together to form a solid sheet of building material. X 96 in 1 4 in. Particleboard tempered hardboard features a smooth surface.

Tempered hardboard adds an additional step of coating the hardboard with a thin film of linseed oil and baking the board to give more water and impact resistance hardness rigidity and tensile strength. The ease of installation affordability and durability makes installing tempered hardboard panels to walls an ideal do it yourself project. Tempered grade hardboard is impregnated under heat with linseed oil making it tougher than standard grade and rendering it more moisture resistant. This tempered hardboard panels features a smooth textured surface that will accept paint.

Tempered hardboard is similar to other types of fiberboard but is usually more dense and water resistant. It is frequently referred to as masonite because it was invented by william h. Furthermore the 23 32 in. Hardboard tempered panel common.

X 48 in x 96 in. Tempered hardboard is strengthened through a process of pressurizing and heating and chemically treated with a thin layer of linseed oil or other drying agent used as a sealant.