Technology Student Wood Laminating

A hot iron is placed on top of the veneer.

Technology student wood laminating. Laminated board for example consists of thin layers of wood bonded together. This warms and melts the glue. The main material used in the manufacture of laminated cartons wood is harvested from sustainable woodlands. It is positioned on the edge of the manmade board natural wood side facing upwards.

Laminated wood is suitable for the head rest back rest and seat of the eames chair. This process fuses a heat sensitive polyethylene film to the surface of card. Similarly laminated fabric consists of two or more layers of cloth joined together with an adhesive or a layer of fabric bonded to a plastic sheet. The two layers are fed into a roller press with the laminate film as the top layer.

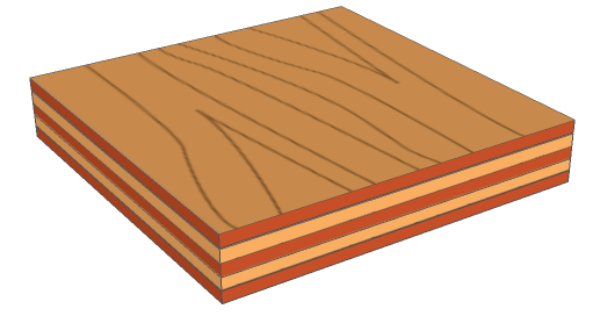

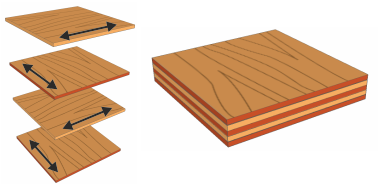

When thin layers of veneer are glued together forming one part they are called laminates. Laminated wood is suitable because it can be formed into relatively complex shapes and forms. A strip of veneer is cut slightly longer than the edge of the board. Students could have a general discussion about wood finishing techniques.

Laminated wood is an inexpensive and functional way of recycling what would otherwise be considered wood waste. The natural wood gives the ideal finish to furniture such as chairs. Design and technology d t ks3. Students to investigate joining methods for plastics and metals.

One side is natural wood and the other is a layer of glue adhesive. Students to investigate adhesives. Complex shapes can even be achieved with one piece of laminated material. You can remove the laminated wood from your mould.

Students to create a fact file on wood lamination joining methods for plastics metals and adhesives. This is achieved by rotating the trunks and as they knock together the bark falls off. The hot lamination process. Many layers of wood are bonded together and the layers are then cut into either planks or sheets.

The top heated roller is lowered on to the card laminate layers as they are automatically fed into the roller press. Complex shapes can be achieved with one piece of laminated material. The steel chromed legs give the chair a contemporary look. Lamination in technology the process of building up successive layers of a substance such as wood or textiles and bonding them with resin to form a finished product.

These planks or sheets are then used for a variety of purposes including making furniture stout flooring and this type of wood is often used in truck beds and vans as well. Students to create a wood laminated wooden chip fork. The resulting tree trunks have their bark removed at a paper mill.